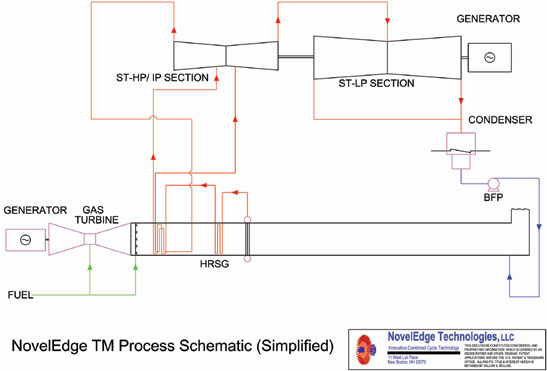

The essence of NovelEdge™

Technology is the ability to utilize a great deal of supplemental

firing to add low cost capacity, only without the detrimental effects

on heat rate that is prevalent in the conventional combined cycle.

To accomplish this task, a unique heat recovery method, in conjunction

with a more efficient bottoming cycle is employed.

The process schematic below illustrates a high-efficiency conventional

combined cycle plant that is typical in the industry. This cycle

utilizes a gas turbine, 3 pressure level HRSG, and a reheat steam

turbine. Design point HRSG stack temperatures are normally in

the 180 to 220 F range. The steam turbine typically provides 30

to 50% of the overall plant capacity (a steam turbine to gas turbine

capacity ratio of 0.43 to 1.0).

The NovelEdge™ Technology

process schematic is similar to the conventional combined cycle

plant in that it utilizes a gas turbine, an HRSG, and a reheat steam

turbine. In addition, design point HRSG stack temperatures are normally

in the 180 to 220 F range. However, the NovelEdge™

Technology HRSG has only one high-pressure drum, versus 3 pressure

levels in the conventional plant. The steam turbine is much larger

and does not require admissions for IP and LP steam. And the amount

of supplemental firing is not as limited as in the conventional

plant, as there is no worry concerning boil-out in the IP section.

For the NovelEdge™ Technology

process, the steam turbine typically provides 50 to 70% of the overall

plant capacity (a steam turbine to gas turbine capacity ratio of

1.0 to 2.3).

EPC contractors, developers, and independent consultants have verified

the performance for this technology. In addition, it has been modeled

on GateCycleTM, from GE Enter Software.

The NovelEdge™ Technology

schematic shown here is in simplified form. For a more detailed

process schematic, along with a process description and performance

runs utilizing GateCycle, please contact

us.

|